Photovoltaic (PV) cables are the unsung heroes of solar energy systems, quietly ensuring that the power harnessed from the sun reaches its destination efficiently and safely. Designed specifically for photovoltaic systems, these cables connect solar panels to inverters, charge controllers, and other components, forming the backbone of renewable energy setups. Understanding the basic components of a PV cable is crucial for anyone involved in solar installations—whether you’re a homeowner, installer, or industry enthusiast. This article dives deep into the anatomy of a PV cable, exploring its key elements, their functions, and why they matter in the grand scheme of solar power generation.

The Critical Role of PV Cables in Solar Energy

As the world pivots toward renewable energy, solar power has emerged as a frontrunner, with photovoltaic systems powering homes, businesses, and even entire grids. At the heart of these systems lies the PV cable—a specialized electrical conduit engineered to withstand the rigors of outdoor environments while delivering electricity with minimal loss. Unlike standard electrical cables, PV cables are built to endure prolonged sunlight exposure, extreme temperatures, and harsh weather, making them indispensable for solar installations.

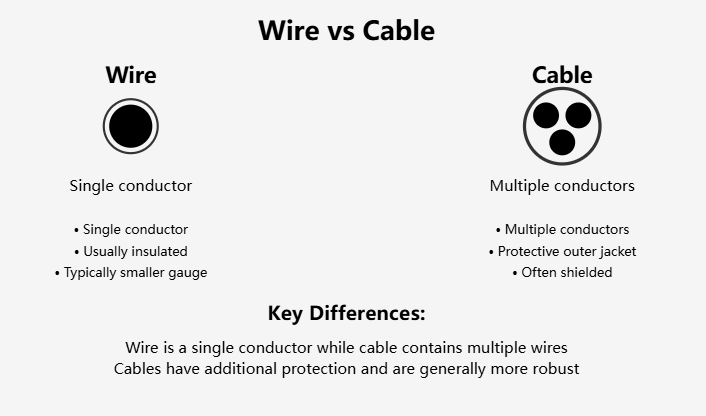

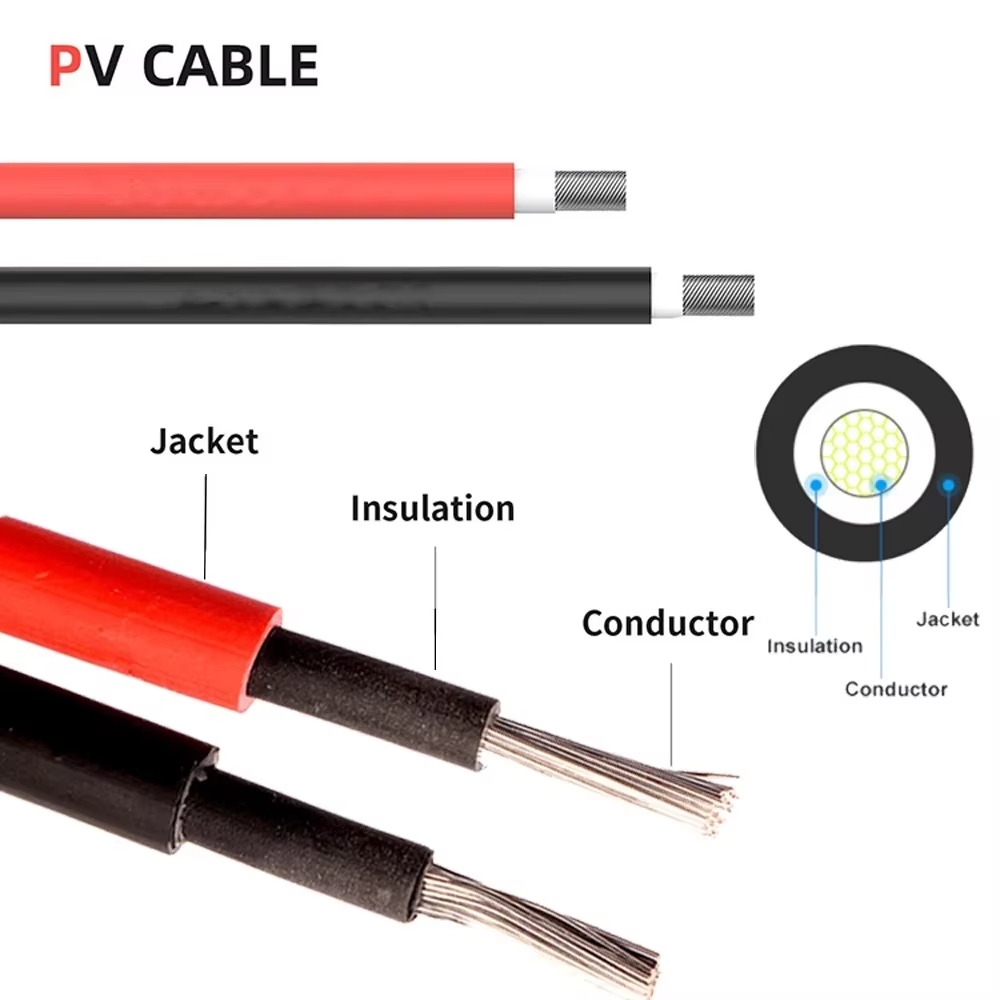

But what exactly makes up a PV cable? This expository essay breaks down its basic components—conductor, insulation, jacket, and often connectors—offering a detailed examination of each. Through four distinct theses, we’ll argue why these elements are not just parts of a cable but critical enablers of solar energy’s reliability, safety, and efficiency. Drawing from recent insights and industry standards, this exploration aims to equip readers with the knowledge to appreciate and select the right PV cables for their needs.

Part 1: The Conductor—Power’s Pathway

The conductor’s material and design determine the efficiency of energy transmission.

The conductor is the core of any PV cable, responsible for carrying electrical current from solar panels to downstream components. Typically made of copper or, less commonly, aluminum, the conductor’s material choice significantly impacts performance. Copper, prized for its superior conductivity and flexibility, is the industry standard for PV cables, ensuring minimal energy loss over long distances . Aluminum, while more cost-effective, offers lower conductivity, making it a secondary option for budget-conscious projects.

The design of the conductor—usually stranded rather than solid—enhances flexibility, allowing installers to navigate the twists and turns of a solar array with ease. Stranded copper conductors, often tinned to resist corrosion, are particularly suited for the outdoor settings where PV systems thrive. For example, a typical PV cable might feature a 10 AWG (American Wire Gauge) stranded copper conductor, rated to handle the high currents generated by modern solar panels . This design ensures efficient power transmission, reducing voltage drop—a critical factor given that IEC 62548 recommends keeping DC voltage drop below 1% for optimal energy yield .

Without a high-quality conductor, even the most advanced solar panels would falter, as energy losses would undermine system efficiency. Thus, the conductor is not merely a component but the lifeline that sustains the flow of renewable power.

Part 2: Insulation—Safety’s Shield

Argument: Insulation protects against electrical hazards and environmental stressors, ensuring long-term reliability.

Surrounding the conductor, the insulation layer serves as a protective barrier, preventing short circuits, electrical shocks, and degradation from external forces. In PV cables, insulation is typically made from advanced materials like cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR), chosen for their durability and resistance to environmental challenges. Unlike the PVC insulation found in standard cables, which may degrade after five to eight years, XLPE insulation can endure the 25- to 30-year lifespan of a solar panel.

This resilience is vital, as PV cables are exposed to relentless sunlight, moisture, and temperature swings—conditions that would compromise lesser materials. For instance, XLPE insulation is UV-resistant and can operate in temperatures ranging from -40°C to 90°C, meeting the stringent requirements of standards like EN 50618 and UL 4703 . These properties ensure that the cable remains safe and functional, even in harsh climates like deserts or coastal regions.

Moreover, insulation safeguards installers and end-users by containing the high DC voltages—often 600V to 2000V—generated by PV systems. A breach in insulation could lead to catastrophic failures, such as fires or system shutdowns, underscoring its role as a non-negotiable safety feature. In essence, insulation transforms the PV cable into a reliable, long-lasting asset rather than a short-lived liability.

Part 3: The Jacket—Armor Against the Elements

The outer jacket enhances durability, making PV cables viable for outdoor use over decades.

Beyond the insulation lies the jacket, the outermost layer of a PV cable, which acts as its first line of defense against the elements. Made from robust materials like XLPE or thermoplastic elastomers (TPE), the jacket is engineered to be UV-resistant, weatherproof, and flame-retardant—qualities that set PV cables apart from conventional wiring [Source: gmsthailand.com]. This outer armor ensures that the cable can withstand rain, snow, and extreme heat without cracking or degrading, a necessity for solar installations that operate outdoors for decades.

The jacket’s importance is evident in its compliance with international standards. For example, the European EN 50618 standard mandates that PV cables resist UV radiation and temperature fluctuations, ensuring consistent quality across installations. Similarly, the NEC’s Article 690 permits only PV wire or USE-2 cables for outdoor PV circuits, both of which feature jackets rated for direct burial or sunlight exposure. A substandard jacket, by contrast, could lead to premature failure, as seen in a 2015 TÜV Rheinland study where 30% of tested PV systems in Germany showed serious defects, often linked to poor-quality cabling [Source: blog.ibc-solar.com].

By shielding the inner components, the jacket extends the cable’s lifespan and reduces maintenance costs, making it a cornerstone of PV system longevity. It’s the unsung protector that keeps solar energy flowing, year after year.

Part 4: Connectors—Seamless Integration

Connectors, though optional, ensure compatibility and ease of installation across PV systems.

While not always considered a core component, connectors are frequently integrated into PV cables to facilitate connections between solar panels, inverters, and other equipment. Typically pre-attached or added during installation, these connectors—such as MC4 types—are designed for quick, secure, and weatherproof linkages [Source: gmsthailand.com]. Their inclusion simplifies the setup process, reducing labor time and potential errors, which is especially valuable in large-scale solar farms.

Connectors must match the cable’s specifications, handling high DC voltages and currents while resisting environmental wear. IP67-rated connectors, for instance, offer dust and water resistance, ensuring reliable performance in outdoor conditions [Source: arrow.com]. Recent studies highlight their significance: PVEL reported that faulty connectors are a leading cause of PV system fires globally, emphasizing the need for quality and proper installation [Source: mayfield.energy]. When paired with a robust PV cable, connectors enhance system modularity, allowing for easy expansion or repairs.

Though optional, connectors bridge the gap between components, making PV cables not just conduits but adaptable solutions. Their role in ensuring seamless integration underscores their value in modern solar setups.

Conclusion: The Sum of the Parts

In the realm of solar energy, PV cables are far more than simple wires; they are precision-engineered systems comprising conductors, insulation, jackets, and often connectors. Each component plays a pivotal role: the conductor ensures efficient power flow, the insulation guarantees safety and reliability, the jacket provides enduring protection, and connectors enable seamless integration. Together, they empower photovoltaic systems to deliver clean energy reliably, even under the harshest conditions.

For consumers and installers, understanding these components is key to making informed choices—selecting cables that balance cost, performance, and longevity. As solar adoption grows, so does the need for high-quality PV cables that uphold the promise of renewable energy. By investing in these foundational elements, we not only harness the sun’s power today but secure its benefits for decades to come.